Carrying out maintenance on electrical switchgear means first of all intervening on it, in order to keep it in a safe and efficient state to prevent possible failures.

Maintenance can be ordinary or extraordinary.

The ordinary maintenance is planned to exclude disservices and to limit the deterioration of the electrical switchgear, while the extraordinary is carried out in the event of a fault or for an intervention that goes beyond ordinary maintenance, such as the execution of restoration works in general as well as modifications and plant improvements.

Main ordinary maintenance activities:

- Verification of the integrity of the switchgear and its main components

- Assessment of mechanical functioning of equipment, such as circuit-breakers and disconnectors

- Control of terminal blocks, connections and of the tightening torques of bolts

- Check of the earthing system and safety systems

- General cleaning activities, often underestimated but of great importance for regular and constant operation over time

Main extraordinary maintenance activities:

- Identification of the fault and its removal

- Inspection of busbars and insulated parts

- Replacement of damaged equipment

- Disconnection of the user concerned to check the insulation resistance and dielectric strength, and restoration of the initial connection

It is essential to draw up an activity plan, written by the Plant Manager according to the information provided by the Electrical Switchgear Technician, who is responsible for collecting and integrating the documentation of the manufacturers of the equipment.

The personnel assigned to this task must be qualified, i.e., an expert in the electrical field.

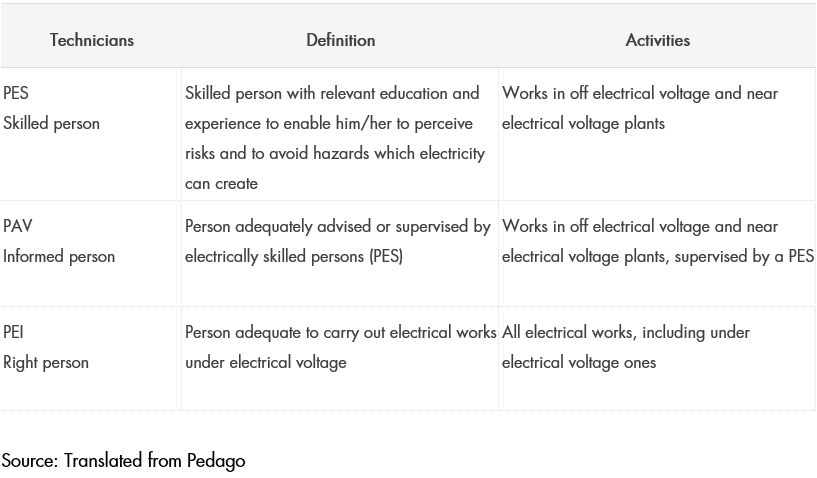

The main operators who intervene on the electrical switchgear are: