C.R. Technology Systems pays attention and care to the choice of materials for the construction of efficient and cutting-edge products, capable to withstand the hardest requests and to respect the environment.

The metal materials and coatings most used in our products are: aluminum, AISI 316 stainless steel, Magnelis® and Sendzimir.

ALUMINIUM

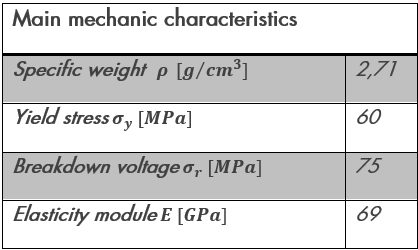

Technical features

Aluminum is a light but strong metal. Its density is 2.71 g / cm³, which corresponds to a specific weight of about one-third of steel and copper, allowing light and robust metal structure.

It can resist to different environments without degrading the material, thanks to excellent corrosion resistance, obtained from the formation of a thin oxidation layer, called “passivation film”. The application of some surface treatments such as anodizing, or the use of protective paints, allows it to resist even in particularly hostile environments, such as marine ones.

Furthermore, its great malleability and ductility, which make this material easy to work, and its high weldability, allow obtaining assembled parts and components with extreme ease and effectiveness.

Sustainability

The production process over the years has been greatly optimized in terms of environmental sustainability. Since the 90s, the industry has reduced its CO2 emissions by 53% for the primary production and more than 90% of PFC emissions related to the electrolytic process of transforming alumina into aluminum.

Moreover, the possibility of recycling this material allows saving 95% of the energy used to produce primary aluminum; an important amount if we think that 40 thousand recycled cans lead to an energy saving equal to 4800 kg of oil and reduce CO2 emissions by 6.5 Mg.

Our applications

Aluminum is widely used in the construction of our shelters, both mobile and fixed.

STAINLESS STEEL AISI 316

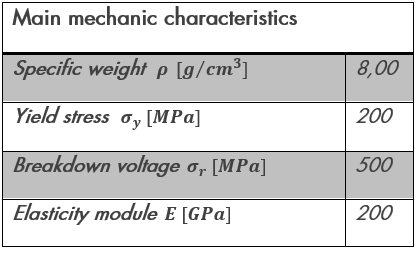

Technical features

AISI 316 stainless steel (X5CrNiMo17-12-2) is one of the most corrosion-resistant materials. It has an austenitic structure with a chromium content between 16% and 18%, nickel between 11% and 14% and molybdenum between 2% and 3%.

It was created as a modification of the X5CrNi1810 steel, by adding 2.5% of molybdenum, thus improving the resistance to electrolytic corrosion (pitting) caused by chlorides.

The presence of molybdenum makes it resistant to corrosion excellent in all natural environments: rural, urban, and industrial waters and atmospheres, even in the presence of a moderate concentration of chlorides and acids. It is particularly suitable for outdoor buildings and for brackish environments.

Sustainability

The long life of the product helps to significantly reduce the amount of material to be disposed. In fact, stainless steel can be demolished or melted in order to generate new sheets, tubes, or bars that, in turn, will be used to construct new components, plants and instruments. It is possible because this material is 100% recyclable and can be used an unlimited number of times, without losing any of its original property.

Our applications

Stainless steel is a material used for the manufacturing of most of our products, in particular those installed in saline and humid environments, or subject to hostile environmental conditions.

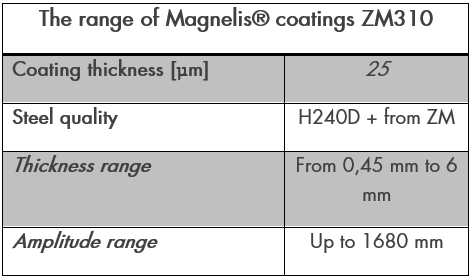

Magnelis®

Technical features

A good alternative to stainless steel is Magnelis®. It is metal-coated steel, which ensures optimal protection of the surface against corrosion-related damages.

Magnelis® is produced on the basis of a classic line of hot-dip galvanized steel, subsequently dipped in a metallic composition of zinc with 3.5% aluminum and 3% magnesium. This coating allows post-galvanized steel to resist up to ten times better than any other galvanized steel, especially in aggressive environments that contain chlorine or ammonia.

Sustainability

It is a REACH compliant material. It has a low environmental impact, thanks to a lower use of zinc compared to a full zinc coating.

The CO2 emissions for the production of Magnelis® are significantly lower than for stainless steel and aluminum. Moreover, it is 100% recyclable and does not contain polluting elements.

Our applications

Magnelis® is suitable for the construction of most of our products, especially those installed in saline and humid environments, or subject to hostile environmental conditions.

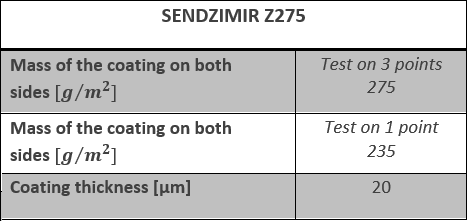

SENDZIMIR

Technical features

Sendzimir is a hot-dip galvanized coating that is applied to steel, by immersing the sheet in a bath of molten zinc, capable of protecting the material from corrosion.

Being less electronegative than steel, zinc acts as a sacrificial anode and consequently, as long as there is zinc on the surface, the steel will not undergo any corrosion.

Sustainability

The use of Sendzimir has a sustainable connotation, since for each ton of hot-dip galvanized steel it is possible to obtain an annual saving of: 4,11kg of CO2; 1,66 t of oil; 68,33 kg of SO2.

Our applications

Sendzimir has an ideal use in the construction of our shelters and our electrical switchgears.